What is a user check and why is it important?

- Wattech Ltd

- Jan 24, 2022

- 3 min read

The user check is an important part of any health and safety process, be it at home or in the workplace, but what is it and why is it so important? To start with a user check is where the person who uses or operates something gives it a quick once over externally to ensure it’s safe to use. An example of a user check is the daily checks that should be carried out on a car, oil and water levels, tyres and breaks.

Now let’s be honest, when was the last time you checked them?

You’re not a mechanic but you can carry out these simple checks.

With the car in mind as an example, the PAT Test can be thought of as an MOT where the item gets a full check over.

Now you have to be a trained mechanic to do an MOT, hence the PAT Tester should be trained like all Wattech staff are.

So what is a user check for electricals?

Firstly it can be carried out with a limited external visual check by anybody no matter of what level of understanding of electrics maybe. The user check for electricals is made up of several different aspects including the plug, connection point (usually the socket), flex and an assessment of the suitability of the item for the environment in which it will be used. Any faults or suspected faults should be reported with faulty equipment being removed from use immediately. Where a risk management system is in place any faults should be logged.

So what should you be looking out for?

When conducting a user check you should check the following:

Plug: Is the plug loose in the socket? Is there any signs of burning? Is the plug damaged for example bent pins, cracks to the casing? Is the case tight and screwed together properly? If the plug is moulded, is the fuse cover in place correctly. Remove the cardboard wiring diagram before use as this is a serious fire risk.

Flex: Is the cable tight in the plug? Is the cable free of snags, cuts, damage? Is the flex long enough for the task? Are the inner cores exposed? Are there any kinks in the lead? Any signs of burning or deterioration? If fixed to the item is it secured and free of damage at the entry to the appliance? If a removable lead such as a kettle lead, is the connector free from damage and is it the right connection.

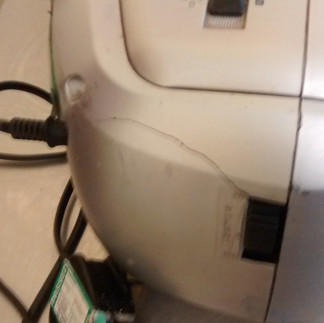

Appliance Check: Is the appliance correct for the job and environment? Is there any signs of burning? Are all safety guards and components in place and as the manufacturer intended? Is there any damage or missing parts? Is there any cracks or damage?

Connection (Sockets/Spurs etc): Is the connection point free of damage and cracks? Any signs of overheating? Is it secured correctly? Is the switch working correctly? If fitted does the RCD trip correctly when pressing the Test (T) button?

Environment: Is the equipment suited to the environment? Do you need to use an extension lead or is there a socket closer? Is the item left on unnecessarily?

Once all the above is completed satisfactory, you can use the item, however if there is a defect or you are unsure, then you should report it and seek qualified assistance.

Where can I get more help?

Wattech staff are always able to help advise and carry out a further inspection, just give us a call on 0800 031 4338.

Comments